I have designed two hydronic (water-heated) seed dryers for Wild Garden Seed. These are not “products” per se as both were purpose-built and I do not have plans to materials lists on offer. Feel free to contact me if you are interested in building your own custom design and I can provide pointers and specs.

Advantages of hydronic heating:

- Even heat throughout

- Avoid scorching/overheating – no point is warmer than the water temperature of 110º-130ºF

- Reduced fire hazard vs. combustion-fired or electric-heated dryers

- Possible integration with existing hydronic greenhouse bench heating or indoor hydronic heat.

Greenhouse dryer

- Four shelves, 3′ x 16′ with Delta-T(TM) heat transfer tubing and manifolds. Three of the four shelves are removable; the system converts from 192 sq. ft of drying area in summer/fall to 192 sq. ft of heated bench area in winter/spring.

- Off-the-shelf 4500-watt electric water heater as heat source, 130ºF water temperature.

- 16 drying screens, 3′ x 4′, four magnetic doors for easy loading/unloading.

- With doors removed, functions as 4500-watt space heater on cold days.

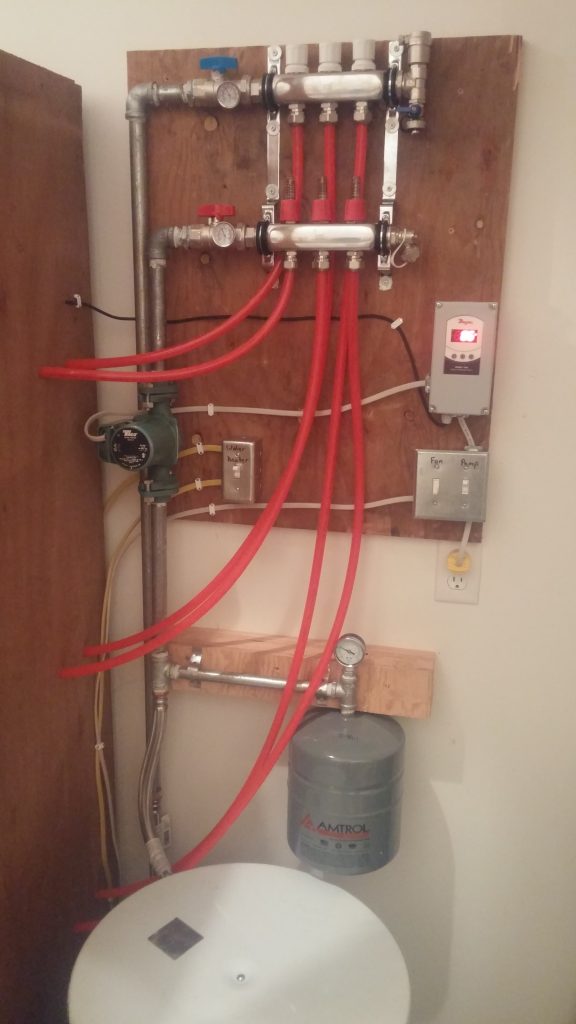

Indoor model

- Shape/size customized to fit in available space.

- Over 300′ of PEX tubing provides very efficient heat transfer: 110ºF water temperature will maintain 85ºF air temperature.

- Enclosed fan and ducts on three sides create steady, one-directional airflow across drying screens.

- Twelve drying screens, 26″ x 30″, total 65 sq. ft. drying area.

- Heat source is 2000-watt, 120V electric water heater.

- Doubles as 2000-watt space heater when vents fully open.